Simple Workbench for Garage or Basement

In my previous post, I started the renovation of my garage "workshop" by reorganizing my tools. After installing a wall area with peg board, I constructed a storage rack for my cordless power tools.

The next step of my garage makeover was to construct a simple workbench. With limited wall space in the garage, the workbench needed to compact, yet big enough for working on smaller projects. Additionally, I wanted it to also function as a storage space for small items, and also allow for storage underneath.

Design

My 1st step was to determine the workbench size. With sheets of 2ft by 4ft plywood readily available at local stores (I used Menards for this project), I decided to save extra wood cutting and use this as the surface footprint. Next, I decided that a 2nd shelf below the main work surface would be great for storing some larger items, keeping them off the floor. Finally, I wanted a way to store small items used at the workbench, so I decided to add 2 small storage drawers just below the main work surface.

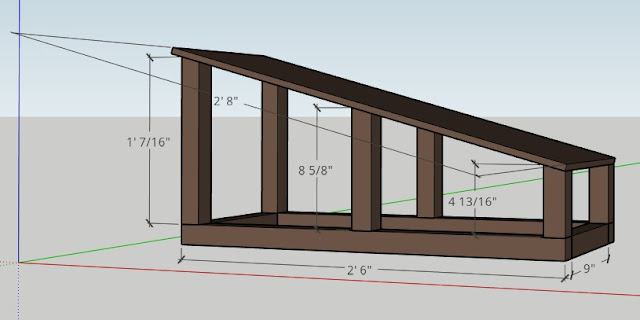

Being a retired design engineer, I wanted to layout this design in a way to accurately establish dimensions. So I fired up my downloaded CAD software Sketchup 3D Design software (free download) on my PC and constructed a virtual model of my workbench.

As I mentioned at the beginning I selected the 2ft by 4ft plywood size to allow me to use common size wood dimensions. Correspondingly, I opted to use 2x4's for the main structure of the workbench. The drawers, since they wouldn't be holding "heavy" items, I opted for lighter weight wood, using 1/2" 2ft x 2ft plywood for the drawer bottoms, and 1"x4" wood for the drawer sides.

My Sketchup model looked like this:

Material

After finishing the dimensional details of this design, I determined the stock material I needed to buy (A copy of the workbench design with a Bill of Material and Purchase Material Listing is included at the end of this article).

As mentioned earlier, I used our local Menards store, as they have a great variety of wood material in various sizes, and all accessible within the store (no driving around to the lumber yard in back to pick up wood). Here's what I picked up:

- ( 2) 24"x48" 3/4" Plywood

- ( 2) 24"x24" 1/2" Plywood

- ( 4) 1"x 4" - 48"

- (11) 2"x 4" - 48" or (6) 2"x4" - 96"

- ( 2) 24" Drawer Slider Sets (Bottom mounting)

- ( 2) Drawer Handles

As for materials to fasten parts:

- Drawer Joints - Phillips head M6 or M8 1-1/2" long

- Carpenter's Glue used on all drawer joints

- Bench Joints - #8 Deck screws

- 1-1/4" Long for mounting plywood to 2x4's

- 2-1/4" Long for connecting 2x4's together

- Carpenter's Glue also used on attaching plywood to 2x4's

Fabrication - Drawers

I decided to tackle the drawers first. Since it's January in Iowa, and my work space is in a detached garage, I opted to assemble the drawers in the basement after cutting the drawer material using the miter saw in the garage.

One issue many will have when buying basic construction wood is straightness. Despite trying to get the "straightest", "flatest" wood, you likely have some warped pieces. For a workbench like this, most deformity can be dealt with. In this case, when attaching the pieces together, I used multiple clamps to position the parts correctly. Then, I added screws and carpenter's glue to the joints, letting the glue set for 24 hours. That seemed to eliminate the visible deformities.

After assembly of the wood pieces, a pull handle was attached to the front. I also attached the drawer portion of the drawer sliders to the bottom edges of each drawer.

Here are "before" and "after" photos of one of the drawers.

Fabrication - Workbench

The 1st step of the workbench was to cut the 2x4's to fit the plywood pieces, and to make the leg heights provide a 33" top work surface. The top surface and lower surface/shelf are the same construction. So I cut (2) sets of the pieces listed below:

- (2) 2"x4" - 48" (Frame - for the width of each surface)

- (3) 2"x4" - 21" (Frame - end pieces and middle piece)

I also cut (4) legs to 33". I selected 33" to allow an appropriate height for working with a band saw and a dual sander. Finally, I cut (2) 2"x4" support pieces 13-1/4" long to place between the top and bottom surfaces. This will provide bench stability, and a 2nd surface to mount the (2) drawer sliders. (Note: the lower surface/shelf can be positioned at any distance from the upper shelf and the floor. I chose this height to allow adequate clearance above the floor, but providing enough shelf height for storing bigger items).

The legs were then attached to the upper and lower surfaces. 2"x4" legs were first mounted flush to the ends of the top surface. The top of 2nd surface was mounted to the legs 16-3/4" below the top surface also using 2-1/4" long deck screws.

Once all (4) legs were attached to both surfaces. the final two support pieces were attached to the upper and lower surfaces after aligning with the front and back edges and positioning in the center (24" from either end. The attaching screws were angled into the support pieces, and then into the surfaces. Here are some photos of this assembly process.

Drawer Installation

To complete the workbench, I needed to assemble the (2) drawers 1/4" below the bottom of the top surface. To do this, I measured the distance from the top of the drawer to the top of the frame slider (3"). I added an additional 1/4" to that dimension to allow clearance to the top surface. I then measured down the workbench legs and the center supports 3-1/4" and made marks. I then positioned the top of the frame slider portion at the 3-1/4" mark, checked that they were level (using a torpedo level), and clamped them into that position. I drilled 1/16" pilot holes in 2 places on each frame slider and installed 2 mounting screws (provided with sliders) in each. This was repeated for all (4) sliders).

Here are shots of the finished product.

Optional Consideration

At this point I began wondering if I should install wheels or adjustable leg levelers. I don't plan on "rolling the workbench around" so no wheels. I opted to install leg levelers, figuring that between the garage floor and my workbench assembly inaccuracy, the (4) workbench legs would likely not be level. So I purchased some levelers similar to these:

These were installed by drilling a 7/16" diameter hole in the bottom of each 2"x4" leg, tapping the T-nuts into each hole, and screwing in the threaded levelers all the way. Once the workbench was stood upright, the levelers were adjusted until the "wobble" was eliminated.

Final Thoughts

This was simple, but functional workbench design. Using standard construction material (plywood, 2x4's and 1x4's) made assembly fairly straight forward. Adding the two drawers added a degree of complexity. But with a little patience and "homework" to make sure all dimensions were checked and double checked, the drawers were a great addition. The cost of material was ~ $165 (plus fasteners). I looked online to see if I could purchase a similar workbench near that price. Not a chance! If you are looking to reduce the cost, eliminate the drawers (~$27), and/or the 2nd surface/shelf (~$43). A single surface workbench that is easy to build for ~$100!

Being new to woodworking, a project like this was perfect. It gave me more experience with determining sizes and configurations that made construction easier. It also gave me more "practice time" with my miter saw, my table saw, and my "clamps". Doesn't seem like a big deal, but for us "newbies", it really helps getting the feel for doing wood working projects.

Stay tuned for the next project I take on!

(Below is a copy of the workbench design with a Bill of Material and Purchase Material Listing included)

Comments

Post a Comment